Funshion is a professional manufacturer and exporter of scooter, skateboard and other sporting toys. With an internationally advanced development center and mold making departments, we offer OEM services for our customers, one-stop for all your problems.

Today, let's talk about the customize services Funshion can offer when our customers want to OEM the pro scooters handlebar and grips.

Handlebar Material:

1. Steel: general elongation, high hardness, the lowest price.

2. Aluminum: it has better elongation and elasticity, and its price is higher than that steel.

3. Chromoly steel: good elongation and elasticity, expensive price.

Pro scooter generally with steel, aluminum material in the majority, high-grade scooter part uses chromoly material, chromoly material is very strong.Aluminum mold shape is fixed, customized mold needs to open, mold opening cost is expensive.The T bar with horizontal bar bending and supporting frame is the most expensive.

Process:

The handle length can be customized, ranging from 450-590mm, with an entry-level recommended length of 500mm.

The surface treatment technology has the spray, the paint, the oxidation, the electroplating price increases successively.We can do it, at present spray plastic in the majority.Oxidation and electroplating are mainly used for high-grade products.

Handlebar Grip Material:

The grip material is PVC/TPR/TPU .Advantages: high elasticity, aging resistance, oil resistance, etc.

From the perspective of material, TPU has the best hand feeling, but the price is the most expensive, because the process of injection molding is relatively waste.We usually use TPR materials, which are moderately priced and feel good.

From the shape, the inside diameter of the grip is usually 22mm, because the tube at the T grip is 22mm in diameter.The factory has fixed several kinds of grip molds. If the customer has special requirements, the molds can be customized.The grip length is 100mm, 110mm,120mm.

The color can be customized, but the MOQ for special color is not in stock (MOQ: 1000PCS).

Process:

The main process of the grip is Plastic injection.

Stunt scooter customized parts -Wheels

Stunt scooter customized parts -Wheels

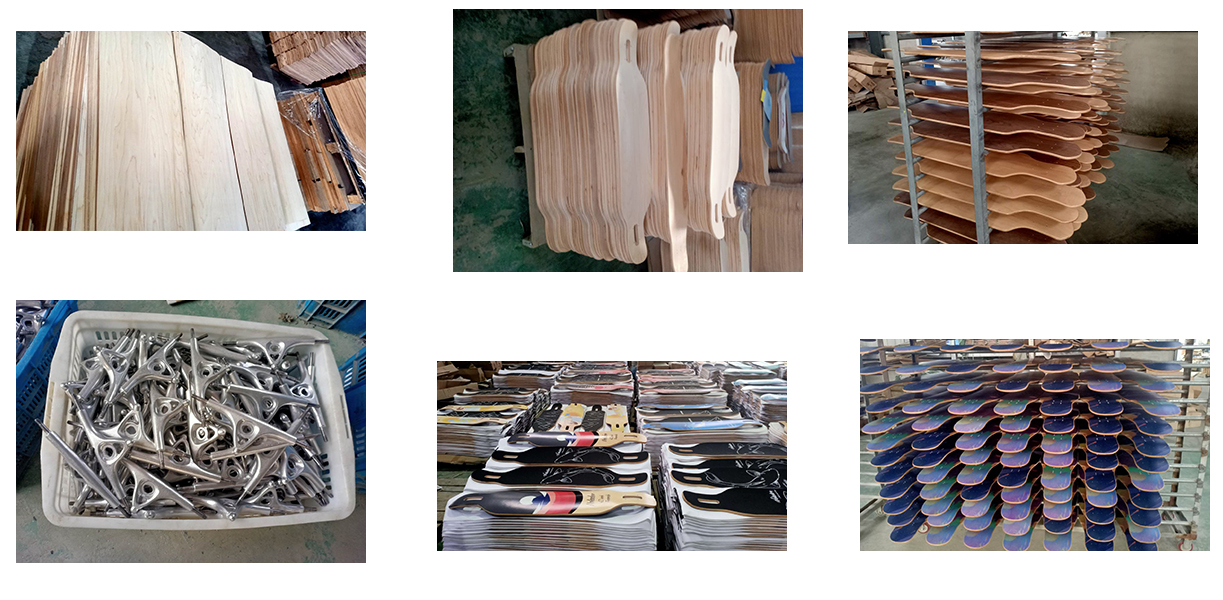

The production process of skateboard

The production process of skateboard