Funshion is a professional manufacturer of skateboards, scooters, electric scooters etc. sporting products since 2008.

Wooden skateboards are one of the main products of our factory.Now, I will introduce the main production process of skateboards in our factory.

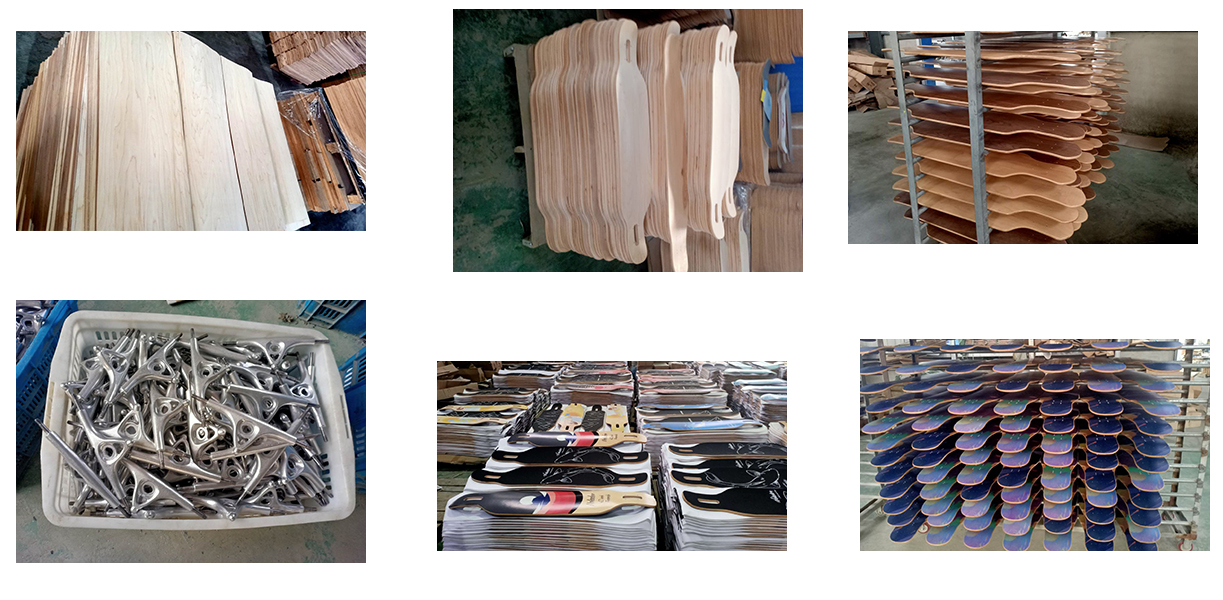

The main production process of skateboard is mainly divided into the following steps:

1.Raw mateial-Cut into the desired shapeand then grind it smooth.

Customers can not only choose the material of the skateboard, but also customize the shape and size of the skateboard.

2.Glue the maple together and press it with a hot press.

In fact, the cold pressure effect is better, but the cold pressure production efficiency is lower.which cannot meet the demand of mass production.

Hot pressing not only has high production efficiency, large output and low price.Of course, we also accept orders for the use of cold pressing process.

3.Let it dry for a while after the hot pressing is done.

This will make the maples closer together and not easy to separate.

4.Heat transfer printing process on the bottom of the skateboard, printing the design and logo required by the customer.

After printing the pattern on the bottom of the skateboard, let it sit for a while to make the pattern clearer and firmer.

5.Stick grip tape with customer logo on the top of the skateboard.

The main types of griptape are 80S, 0S780 and AB80, which is required by customers.

6.Assemble the various parts of the skateboard.

The material, size, color and logo printed on the Truck and wheel can be customized.

Customers can also choose screws and bearings of different grades and quality.Screws are generally of class 8.8, class 10.8 and class 12.8. Bearings are generally divided into ABEC-5, ABEC-7 and ABEC-9.Generally speaking, our factory will use class 10.8 screws and ABEC-9 bearings.

7.Packaging.

Customize the color box accordance with the packaging designs of customers.

Stunt scooter customized parts -Wheels

Stunt scooter customized parts -Wheels

Stunt scooter customized parts -Handlebar

Stunt scooter customized parts -Handlebar